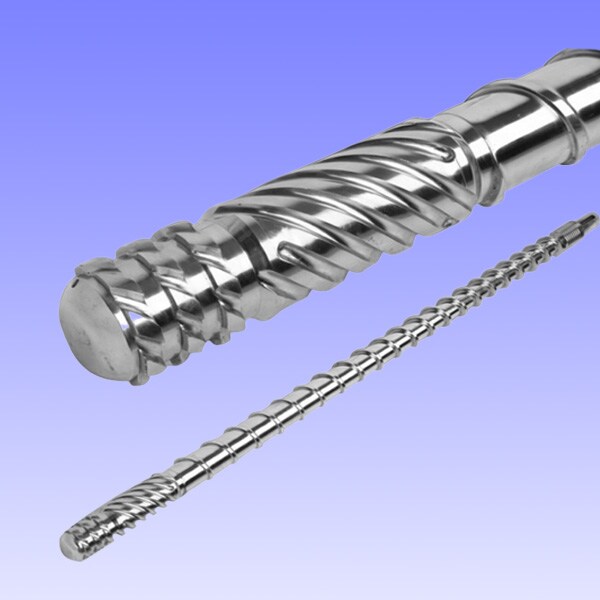

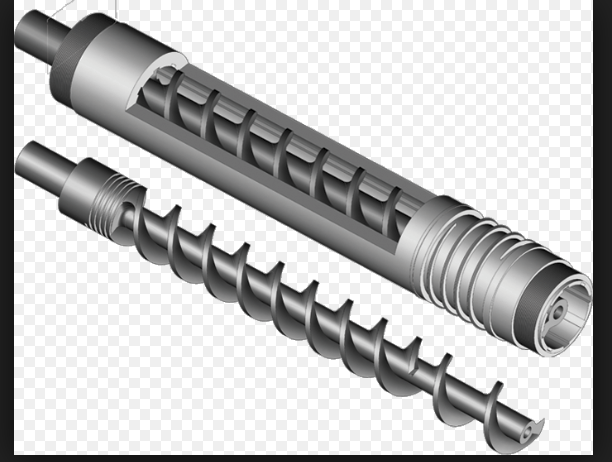

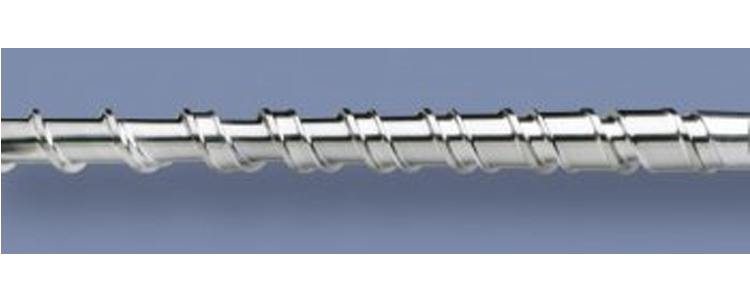

Barrier Screw

Barrier screws are a way to increase throughput of single-screw extruders and to improve melt quality. They keep unmelted solids in the primary screw channel by increasing the flight clearance on the downstream side, while letting the fluid melt escape over the barrier flight into the secondary channel. That way, the solids do not randomly disperse into the metering section. This allows for extrusion at higher pressures and higher rates without sacrificing melt quality.

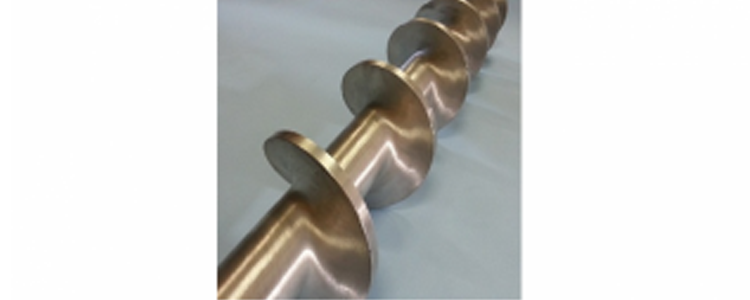

Single Screw

Screw design is critical for increasing output from your machine, at Deep Industries we are making high speed, high output single screw for Plastics, Rubber, Food, Petrochemical, Pharmaceutical processings.

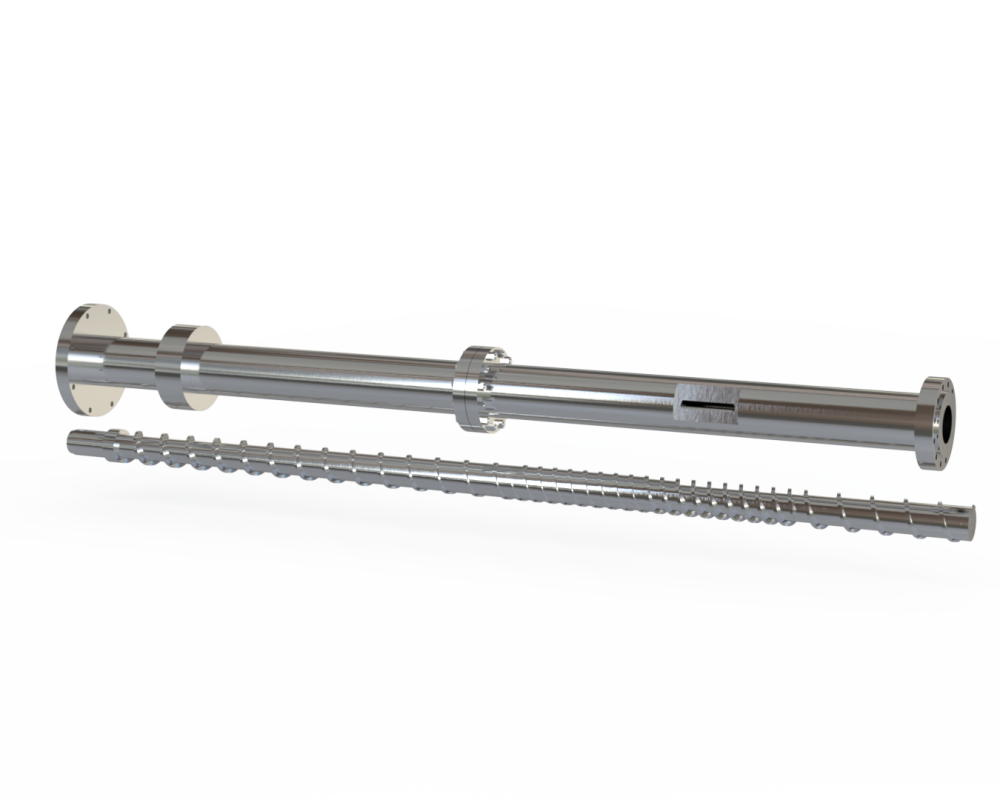

Single Screw Barrel

Our Single Screw Barrel are manufactured using advanced technology and machine which provide various features such as strong ability, durability, exact fitting, easy to use and remove etc. our products are specially designed to meet customers specific need and requirements.

Screw Barrel

At Deep Industries, we specialize exclusively in screw barrel engineering, and we’ve been perfecting it for over 20 years. This singular focus has helped us build a reputation for exceptional quality and trusted customer relationships—setting us apart in a competitive market.

Barrier Screw Barrel

One of the advantages of barrier screws is that for the most part they eliminate the problems associated with solids-bed breakup that are typical in conventionally flighted screws. Many conventional screws have to rely on restrictive mixing sections to complete the melting process because solids conveyed into the metering section are difficult to melt.

Torpedo for Injection Moulding machine

We offer a broad range of product which used in various industrial applications. These products are manufactured using standard quality EN41B Musco Material which is procured from reputed and trusted supplier. These are most common type of torpedo. Our torpedo are manufactured using advanced technology and machine which provide various features such as strong ability, durability, exact fitting, easy to use and remove etc.

Ring Plunger Set

Injection molding apparatus wherein a torpedo is mounted at the front end of a nozzle to provide a fixed ring gate. The torpedo has an elongated central shaft with a nose portion which projects forwardly into a cylindrical opening extending through the mold to the cavity. The outer surface of the nose portion is sufficiently spaced from the inner surface of the opening to form the ring gate through which the melt flows into the cavity. The nose portion of the central shaft enhances heat transfer during the injection cycle and thus reduces cycle time and provides cleaner gates.

Grooved Feed Sleeve

Grooved Feed can increase output and reduce melt temperature. But these throats are not for every application. They have specific applications, with many polymers, grooved-feed extruders produce 20-40% higher output per rpm than the same diameter extruder with a smooth feed bore. A grooved feed section improves solids conveying and increases extruder pumping action, thereby raising output at a given extruder rpm, reducing energy put into the polymer, and lowering melt temperature.

Groove Feed Bush and Sleeved Barrel

The grooved feed throat is intensively cooled so the material would not prematurely melt and hinder pressure development. The pressure from the grooved feed throat transfers through the barrel, counteracting the discharge-pressure resistance. If the feed-throat pressure development exceeds the discharge pressure, the output will exceed the drag flow, resulting in further throughput gains.

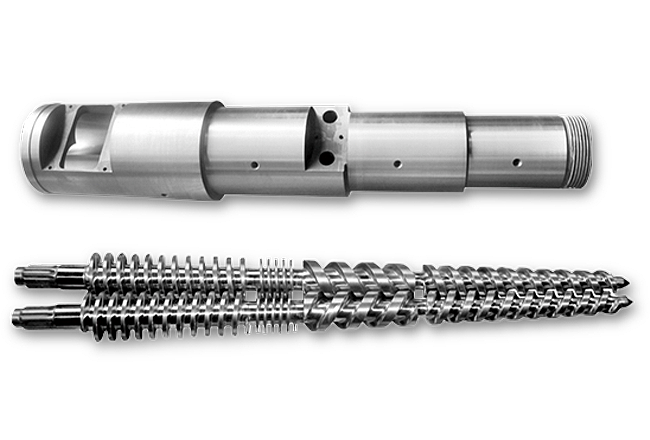

Conical Screw Barrel

We are largest and reputed manufacturer and supplier of Conical Screw Barrel in Umbergaon. We offer a broad range of product which used in various industrial applications. Application: UPVC profile extrusion, CPVC pipe extrusion, Polymer Compounding, WPC extrusion.

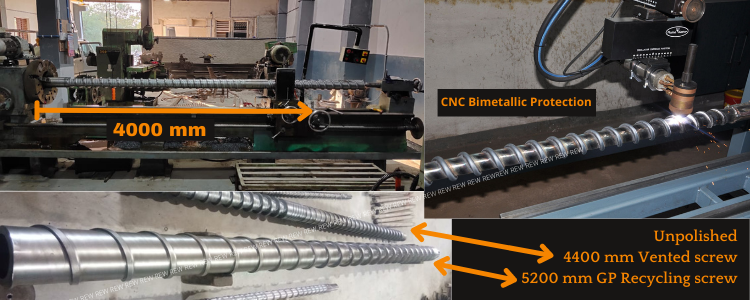

Vented Screw

Vented screw are two stage screw which works to remove volatilities of processing polymers during extrusion of different plastics. The position of vent in the barrel is very important, but the most important thing is to design both stages according to customer's need. Because output of Vented screw depends on both stages.

Vented Screw Barrel

Vented screws are essentially two screws in one. A vented or two-stage screw is essentially two screws on the same shaft. The first works as a conventional screw by feeding, melting, and conveying the polymer forward. The second screw does the same, except it is melt-fed by the first screw. The first screw operates with no head pressure, while the second has to overcome any head pressure from the die and other downstream components.

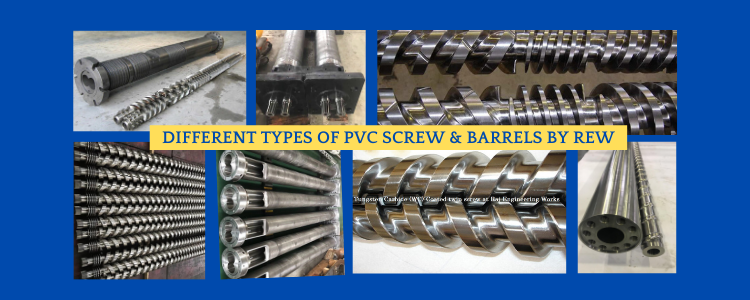

PVC Screw Barrel

We offer a wide range of Screws & Barrels compatible with applications such as PVC pipes and sheets, bottles, compounds, masterbatch, furniture profiles, recycled granules, PVC hoses, garden pipes, braided PVC hoses, flexible suction hoses, as well as for PVC injection molding, extrusion, and blow molding processes.

Customised Screw Barrel

We specialize in manufacturing screw barrel sets tailored to your specific requirements for extrusion plants, blow molding units, and injection molding machines. Whether you need a unique design or a replacement, we offer customized solutions at competitive prices to meet your production needs.

Food Processing Screw Barrel Manufacturer

We design and manufacture high-quality screw barrel sets specifically engineered for food processing applications. Built with food-grade materials and precision engineering, our screw barrels ensure hygiene, durability, and consistent performance. Customized solutions are available to meet your exact processing requirements.

Rubber Processing Screw Barrel

We manufacture robust and wear-resistant screw barrel sets designed specifically for rubber processing applications. Engineered to handle high temperatures and demanding materials, our screw barrels ensure efficient mixing, consistent output, and long service life. Custom designs are available to suit various rubber extrusion and molding machines.

Soap Extruder Screw

We offer precision-engineered screw barrels for soap extruders, designed to deliver efficient mixing, smooth extrusion, and consistent shaping of soap products. Manufactured with high-quality materials for enhanced durability and corrosion resistance, our screws can be customized to meet the specific needs of your soap production line.

Nitrided Screw Barrel

We manufacture high-performance nitrided screw barrels, known for their excellent wear resistance, corrosion protection, and extended service life. Ideal for processing a wide range of materials, our nitrided barrels undergo a controlled nitriding treatment to enhance surface hardness and durability. Customization is available to match your specific machine and application requirements.

Polyester Staple Fibre (RPSF) Plant Screw

We design and manufacture high-precision screws specifically for Polyester Staple Fibre (RPSF) plants. Our screws are engineered for optimal melt quality, high output, and reliable fiber consistency. Built with wear- and corrosion-resistant materials, these screws are ideal for continuous, high-performance operation in synthetic fiber production lines. Custom designs are available to suit your plant’s specifications.

Wire Cable Extruder Screw Barrel

We manufacture precision screw barrels specifically designed for wire and cable extrusion lines. Engineered for smooth material flow, uniform insulation, and high-performance output, our screw barrels ensure optimal processing of PVC, PE, XLPE, and other cable-grade compounds. Durable, wear-resistant, and fully customizable to match your extruder specifications.

Plastic Recycling & Granule Making Screw Barrel

We offer high-performance screw barrels designed for plastic recycling and granule (pellet) production. Built to handle a wide range of recycled materials, our screw barrels ensure efficient melting, thorough mixing, and consistent pellet output. Made from wear- and corrosion-resistant materials, they are ideal for single and twin-screw extruders. Customization options are available to meet specific production needs.

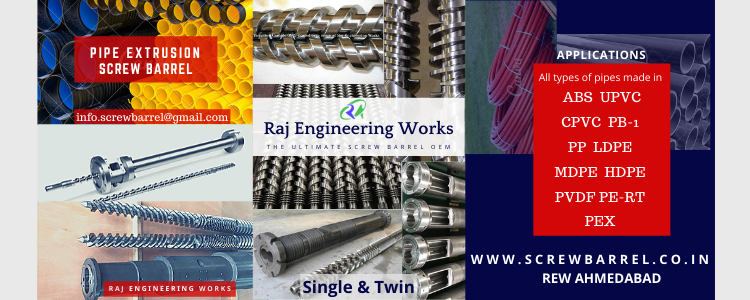

Plastic Pipe Extrusion Screw Barrel

We manufacture high-precision screw barrels specifically engineered for plastic pipe extrusion lines. Designed to ensure uniform melt flow, excellent plasticizing performance, and high output, our screw barrels are suitable for processing a wide range of materials including PVC, HDPE, LDPE, and PP. Built with wear-resistant alloys and customizable to fit various extruder models, our solutions support consistent pipe quality and long-term durability.

Lamination, PP/TQ Film & Raffia Tape Screw Barrel

We manufacture high-performance screw barrels tailored for lamination, PP/TQ film, and raffia tape extrusion applications. Designed for optimal plasticizing, uniform melt flow, and superior film or tape quality, our screw barrels support efficient processing of PP and other thermoplastics. Built from durable, wear- and corrosion-resistant materials, these screw barrels are customizable to meet your specific machine and production requirements.

Tarpaulin & Blown Film Plant Screw Barrel

We design and manufacture high-quality screw barrels for tarpaulin and blown film extrusion plants. Engineered for excellent melt homogenization, stable output, and consistent film thickness, our screw barrels are ideal for processing LDPE, LLDPE, HDPE, and other film-grade materials. Built for durability and long service life, they can be customized to fit various extruder models and production requirements.

PP/HDPE Box Strapping, Sutli & Monofilament Plant Screw Barrel

We manufacture precision-engineered screw barrels specifically designed for PP and HDPE box strapping, sutli, and monofilament production lines. Our screw barrels ensure optimal melting, excellent material homogenization, and consistent output quality. Made from wear-resistant materials, they are built to withstand demanding processing conditions and can be customized to fit your extrusion equipment and production needs.

Tyre Plant (Automobile Tire) Screw

We specialize in manufacturing durable and high-performance screws for automobile tire production. Designed to handle tough rubber compounds, our screws ensure efficient mixing, uniform extrusion, and consistent quality in tire manufacturing. Made from wear-resistant materials and customizable to fit your tire extrusion or molding machines, our screws deliver reliability and long service life.

WPC Screw Barrel

We manufacture specialized screw barrels for Wood Plastic Composite (WPC) production. Engineered to provide excellent mixing, efficient melting, and consistent output, our screw barrels are designed to handle the unique challenges of WPC materials. Made from wear-resistant materials, they ensure durability and long service life. Custom solutions are available to fit your extrusion equipment and production requirements.

Injection Molding Screw Barrels

We produce high-precision screw barrels specifically designed for injection molding machines. Our barrels ensure optimal plasticizing, uniform melt flow, and consistent part quality across various thermoplastic materials. Manufactured with wear-resistant materials and customizable to fit different machine models, our screw barrels enhance productivity and durability in injection molding operations.

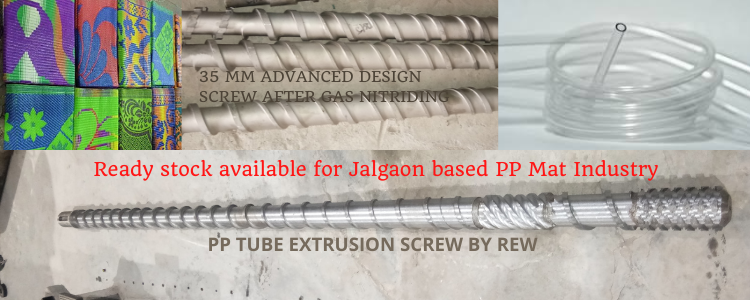

Plastic Mat & PP Tube Extruder Screw Barrel

We manufacture precision-engineered screw barrels designed for plastic mat and PP tube extrusion processes. Our screw barrels provide efficient melting, uniform material flow, and consistent product quality. Made with durable, wear-resistant materials, they are customizable to fit various extruder models, ensuring reliable performance and long service life in mat and tube production.

Plastic Machine Screw Barrel Manufacturer

We specialize in manufacturing high-quality screw barrels for plastic processing machines, including extruders and injection molding equipment. Our screw barrels are engineered for optimal melting, uniform flow, and enhanced durability. Custom designs are available to suit various machine models and processing requirements, ensuring efficient and reliable production.

Polypropylene Staple Fibre (PPSF) & Polypropylene (PP) Spunbond Nonwoven Fabric Plant Screw Barrel

We manufacture precision-engineered screw barrels specifically designed for Polypropylene Staple Fibre (PPSF) and PP spunbond nonwoven fabric production plants. Our screw barrels ensure optimal melting, excellent polymer flow, and consistent fiber quality, supporting high-efficiency and continuous operation. Constructed from wear-resistant materials, they offer durability and long service life. Customization options are available to fit various extrusion systems and production specifications.

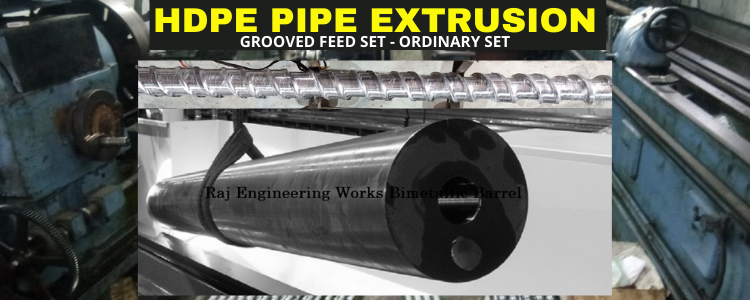

HDPE Pipe Extrusion Screw Barrel

We specialize in manufacturing high-quality screw barrels designed for HDPE pipe extrusion. Engineered for uniform melting, efficient plasticizing, and stable output, our screw barrels ensure consistent pipe quality and long-lasting performance. Made from wear-resistant materials and customizable to suit various extruder models, they support reliable and efficient HDPE pipe production.

PET Recycling Screw Barrel

We manufacture specialized screw barrels designed for efficient PET recycling processes. Our screw barrels are engineered to handle the unique challenges of PET materials, ensuring thorough melting, effective decontamination, and consistent pellet quality. Made from wear- and corrosion-resistant materials, they provide durability and reliable performance in recycling extruders. Custom designs are available to fit your specific recycling equipment and production needs.

Nylon (PA) Extrusion Screw Barrel

We manufacture high-performance screw barrels specifically designed for Nylon (PA) extrusion applications. Engineered for excellent thermal stability, efficient plasticizing, and uniform melt flow, our screw barrels ensure consistent product quality for demanding engineering plastics like PA6 and PA66. Made from high-grade, wear-resistant materials, and customizable to fit various extruder models, our screw barrels deliver durability and precision for nylon processing.

LSR / LIM Silicone Extrusion & Injection Moulding Screw Barrel Manufacturer

We specialize in manufacturing precision screw barrels for Liquid Silicone Rubber (LSR) and Liquid Injection Molding (LIM) systems. Our screw barrels are designed to handle the unique flow characteristics and temperature sensitivity of silicone materials, ensuring excellent metering, consistent output, and contamination-free processing. Suitable for both extrusion and injection molding applications, our barrels are made from corrosion- and wear-resistant materials and can be fully customized to match your specific machine and process requirements.

Polycarbonate (pc) Processing Screw Barrel

We manufacture high-precision screw barrels specifically designed for processing Polycarbonate (PC). Engineered for excellent thermal control, uniform plasticizing, and smooth material flow, our screw barrels ensure high transparency and dimensional stability in PC products. Made from high wear- and corrosion-resistant materials, they are ideal for both extrusion and injection molding applications. Custom designs are available to suit your machine and processing requirements.

ABS, PE & Polyolefin Injection Molding Screw Barrel

We manufacture high-performance screw barrels tailored for injection molding of ABS, PE, and other polyolefin materials. Designed for optimal thermal control, consistent plasticizing, and smooth injection flow, our screw barrels ensure excellent part quality and processing stability. Built with wear- and corrosion-resistant materials, they are ideal for high-output production and are fully customizable to fit various injection molding machine models and material requirements.

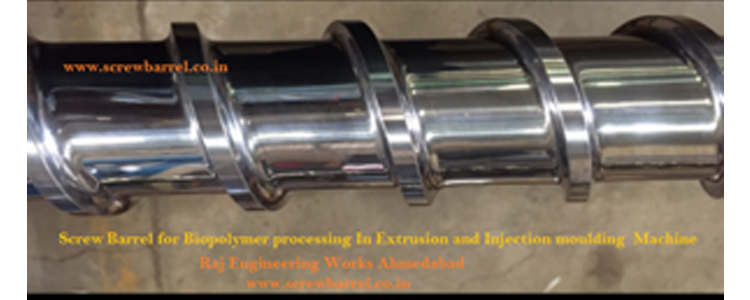

Screw Barrel for Biopolymer Processing

We design and manufacture specialized screw barrels for processing biopolymers such as PLA, PHA, PBS, and other biodegradable materials. Our screw barrels ensure gentle yet efficient plasticizing, precise temperature control, and consistent melt quality—crucial for maintaining the structural integrity of eco-friendly polymers. Made from corrosion- and wear-resistant materials, these barrels are fully customizable to suit both extrusion and injection molding machines used in sustainable manufacturing.

Polyurethane (PU) Processing Screw Barrel

We manufacture high-quality screw barrels specifically designed for polyurethane (PU) processing applications. Engineered to handle the unique characteristics of PU, our screw barrels ensure precise temperature control, efficient mixing, and smooth material flow. Built from corrosion- and abrasion-resistant materials, they are ideal for both extrusion and injection molding of PU products. Custom designs are available to meet your specific machine and production requirements.

Extrusion Screw Barrel

We specialize in manufacturing high-performance screw barrels for all types of plastic and rubber extrusion processes. Designed for optimal plasticizing, efficient material flow, and consistent output, our screw barrels are suitable for a wide range of materials including PVC, HDPE, LDPE, PP, ABS, and more. Made from wear- and corrosion-resistant alloys, our barrels are durable, reliable, and fully customizable to suit your extrusion machinery and production needs.

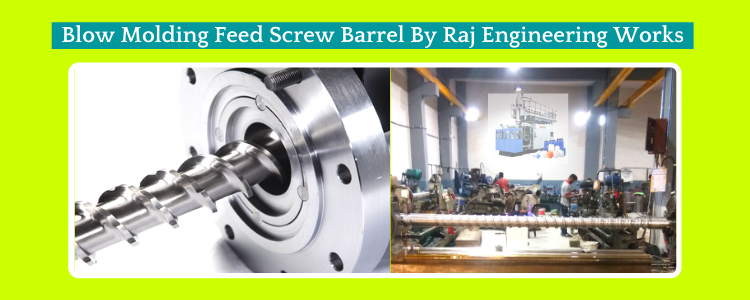

Blow Moulding Screw Barrel OEM

As an OEM supplier, we manufacture high-quality screw barrels tailored for blow moulding applications. Our screw barrels are engineered for precise plasticizing, consistent parison quality, and efficient material flow—ideal for processing HDPE, PP, PVC, and other blow moulding grades. Built with wear- and corrosion-resistant materials, we offer complete customization to meet the specifications of your blow moulding machines and production requirements.

Screw Barrel for Aluminium Composite Panel (ACP) Sheet Extrusion

We manufacture precision-engineered screw barrels specially designed for Aluminium Composite Panel (ACP) sheet extrusion lines. Our screw barrels ensure uniform melting, excellent material dispersion, and consistent layer bonding—crucial for high-quality ACP production. Made from high-strength, wear- and corrosion-resistant materials, these barrels are customizable to match your extruder specifications and are suitable for both core and surface material processing.

Cast Film Extrusion Screw Barrel

We specialize in manufacturing high-performance screw barrels for cast film extrusion lines. Engineered for precise temperature control, uniform melt flow, and superior film clarity, our screw barrels are ideal for processing polymers such as PP, PE, PET, and EVA. Made from wear- and corrosion-resistant materials, they ensure long-lasting performance and can be fully customized to meet your specific machine and production requirements.

Recycling Screw Barrel

We manufacture durable and high-performance screw barrels designed specifically for plastic recycling applications. Our screw barrels ensure efficient melting, thorough degassing, and consistent pelletizing of recycled materials such as HDPE, LDPE, PP, PET, and more. Built from wear- and corrosion-resistant materials, they are engineered for long service life under demanding recycling conditions. Custom designs are available for single-screw, twin-screw, and vented extruder systems.

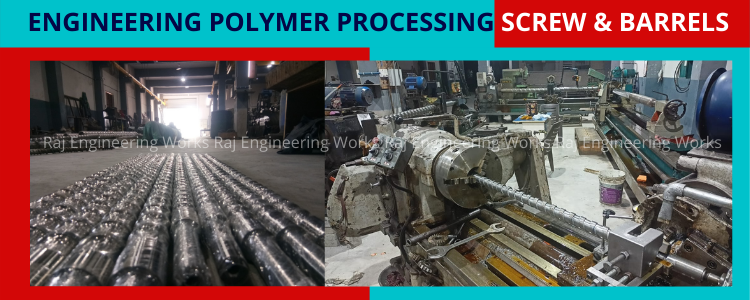

Engineering Polymer Screw Barrel

We design and manufacture high-performance screw barrels specifically for processing engineering polymers such as PC, PA, PBT, PEEK, ABS, and PPS. Engineered for precise temperature control, excellent shear stability, and uniform plasticizing, our screw barrels ensure consistent output and high product quality. Made from premium wear- and corrosion-resistant materials, they are ideal for high-temperature, high-viscosity materials and can be customized to fit both extrusion and injection molding machines.

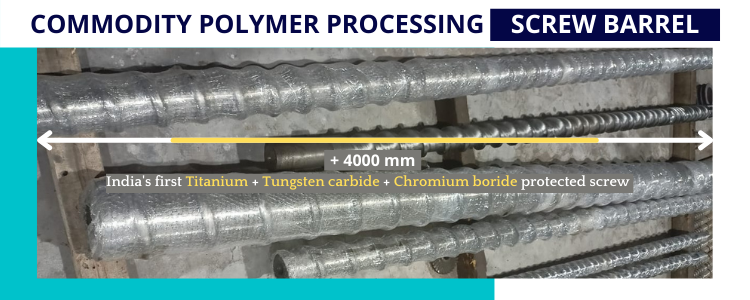

Commodity Polymer Screw Barrel

We specialize in manufacturing screw barrels for processing commodity polymers such as PE, PP, PVC, PS, and PET. Designed for high-volume production, our screw barrels offer efficient plasticizing, smooth material flow, and consistent output—ideal for packaging, household goods, and consumer products.

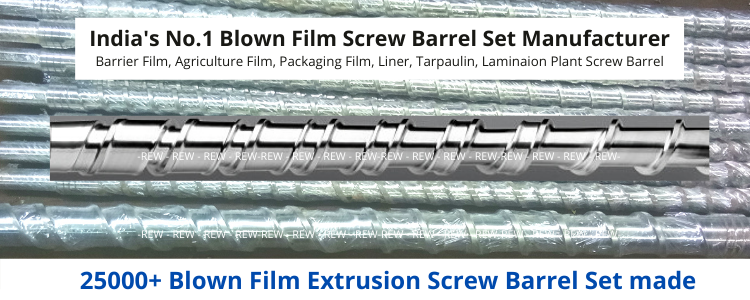

Blown Film Screw Barrel

We manufacture high-performance screw barrels tailored for blown film extrusion lines. Designed for excellent melt homogenization, stable output, and superior film clarity.

Bimetallic Screw Barrel

High-quality bimetallic screw barrels designed for superior wear and corrosion resistance in plastic and rubber processing.

Super Trimetallic Screw Barrel – Extreme Performance & Maximum Wear Resistance

Top-tier trimetallic screw barrels offering extreme abrasion, corrosion, and heat resistance for demanding applications.